Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 199 2458 0075

A color sorter is a sophisticated piece of equipment that plays a crucial role in sorting a wide range of materials based on their visual characteristics. Here's a detailed look at what it does:

1. Visual Detection and Analysis

Color Identification: The primary function of a color sorter is to distinguish different colors. It uses high - resolution cameras or optical sensors to capture the visual appearance of objects as they pass through the sorting chamber. For example, in a rice - sorting application, it can tell the difference between pure white grains and those with a yellowish tint, which might indicate spoilage or immaturity.

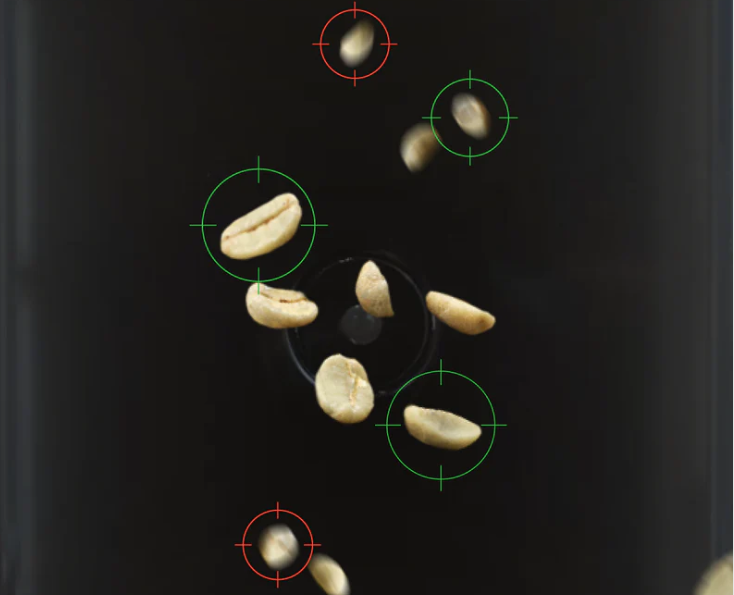

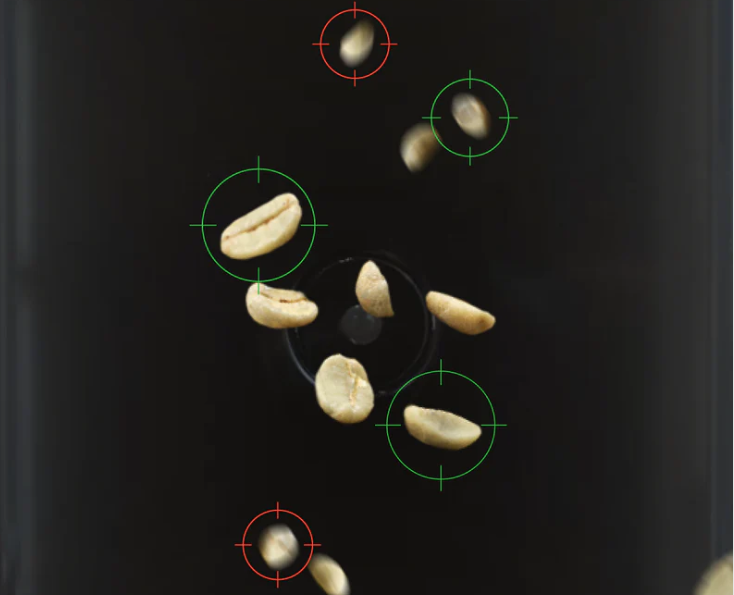

Shape and Size Analysis: In addition to color, many modern color sorters can also analyze the shape and size of objects. They use advanced image - processing algorithms to determine if an object has the correct geometric characteristics. For instance, in the sorting of nuts, it can identify nuts that are broken or have an irregular shape, in addition to color differences.

2. Sorting Based on Criteria

Separation of Defective and Non - Defective Items: One of the most important functions is to separate defective or unwanted materials from the good ones. In the food industry, for example, it can remove discolored grains, fruits with blemishes, or nuts with cracks. In industrial applications such as plastics recycling, it can separate plastics of the wrong color or those that are contaminated.

Grading and Classification: Color sorters can also grade materials according to specific quality standards. For example, in the sorting of coffee beans, they can classify beans into different grades based on color, which often correlates with flavor and quality. In the mining industry, ores can be sorted and graded according to their mineral content and quality as determined by color and other visual features.

3. High - Speed and Precision Sorting

Efficient Throughput: Color sorters are designed to handle a large volume of materials in a relatively short time. They can operate at high speeds, sorting thousands of objects per minute. This high - speed sorting capability is essential for industries that deal with large - scale production, such as agriculture and food processing.

Precision Sorting: Despite the high speed, color sorters maintain a high level of precision. The accuracy of their sorting depends on the sophistication of the optical and image - processing systems. The better - quality sorters can achieve a very high level of accuracy, ensuring that only the desired materials are selected and the rest are effectively removed.

4. Customizable Sorting Parameters

Adjustable Criteria: Users can adjust the sorting criteria according to their specific needs. For example, in a seed - sorting operation, the operator can set the color range for acceptable seeds, as well as the tolerance for shape and size deviations. This flexibility allows the color sorter to be used for a wide variety of materials and different quality requirements.

Multiple - Criteria Sorting: Some advanced color sorters can sort based on multiple criteria simultaneously. For example, in the sorting of gemstones, they can consider color, transparency, and shape all at once to separate high - quality gemstones from lower - quality ones and waste materials.

A color sorter is a sophisticated piece of equipment that plays a crucial role in sorting a wide range of materials based on their visual characteristics. Here's a detailed look at what it does:

1. Visual Detection and Analysis

Color Identification: The primary function of a color sorter is to distinguish different colors. It uses high - resolution cameras or optical sensors to capture the visual appearance of objects as they pass through the sorting chamber. For example, in a rice - sorting application, it can tell the difference between pure white grains and those with a yellowish tint, which might indicate spoilage or immaturity.

Shape and Size Analysis: In addition to color, many modern color sorters can also analyze the shape and size of objects. They use advanced image - processing algorithms to determine if an object has the correct geometric characteristics. For instance, in the sorting of nuts, it can identify nuts that are broken or have an irregular shape, in addition to color differences.

2. Sorting Based on Criteria

Separation of Defective and Non - Defective Items: One of the most important functions is to separate defective or unwanted materials from the good ones. In the food industry, for example, it can remove discolored grains, fruits with blemishes, or nuts with cracks. In industrial applications such as plastics recycling, it can separate plastics of the wrong color or those that are contaminated.

Grading and Classification: Color sorters can also grade materials according to specific quality standards. For example, in the sorting of coffee beans, they can classify beans into different grades based on color, which often correlates with flavor and quality. In the mining industry, ores can be sorted and graded according to their mineral content and quality as determined by color and other visual features.

3. High - Speed and Precision Sorting

Efficient Throughput: Color sorters are designed to handle a large volume of materials in a relatively short time. They can operate at high speeds, sorting thousands of objects per minute. This high - speed sorting capability is essential for industries that deal with large - scale production, such as agriculture and food processing.

Precision Sorting: Despite the high speed, color sorters maintain a high level of precision. The accuracy of their sorting depends on the sophistication of the optical and image - processing systems. The better - quality sorters can achieve a very high level of accuracy, ensuring that only the desired materials are selected and the rest are effectively removed.

4. Customizable Sorting Parameters

Adjustable Criteria: Users can adjust the sorting criteria according to their specific needs. For example, in a seed - sorting operation, the operator can set the color range for acceptable seeds, as well as the tolerance for shape and size deviations. This flexibility allows the color sorter to be used for a wide variety of materials and different quality requirements.

Multiple - Criteria Sorting: Some advanced color sorters can sort based on multiple criteria simultaneously. For example, in the sorting of gemstones, they can consider color, transparency, and shape all at once to separate high - quality gemstones from lower - quality ones and waste materials.

With the continuous development of the hazelnut industry, higher requirements are put forward for the sorting process in the hazelnut processing. The integrated solution of Hazelnut color and shell sorting launched by us aims to provide enterprises...

In the dynamic world of the food processing industry, the process of sorting beans plays a pivotal role. But what does it mean to sort beans exactly? Sorting beans is the meticulous process of separating them based on various characteristics such a...

Colour Sorter for Grain - Elevating Agricultural Product Standards WESORT Grain Sorter removes defective grains from a stock of uneven quality products! Suitable for all grains (wheat, barley, rye, etc.), even peas and beans. Moldy, broken, gre...

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in ...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

In the competitive world of agriculture, seed quality is crucial to achieving optimal crop yields and healthy, consistent growth. Whether you're cultivating field crops, herbage, or vegetables, ensuring that your seeds are free from defects and con...

Achieving the best quality in coffee roasting requires precision, and bean sorting plays a pivotal role in ensuring every cup meets the highest standards. Whether you're a small artisan roaster or part of a large-scale coffee production facility, i...

Plastic Sorting Made Easy with WESORT In today’s plastic recycling industry, achieving high-purity materials is crucial for profitability and sustainability. WESORT offers advanced optical sorting solutions designed to enhance both yield and quali...

Coffee, as one of the most popular drinks in the world, has a rigorous process behind it from coffee beans to every cup of fragrant coffee in the hands of consumers, and the color sorting link is the key to ensuring the quality of coffee. Today, I ...

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts: I. Picking and preliminary ...

In today’s competitive coffee market, quality is everything. Every bean that makes it into your blend must be perfect, ensuring the best flavor, aroma, and consistency in every cup. Our cutting-edge AI-powered single-channel coffee bean optical so...

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor pr...

Some time ago, I’ve witnessed firsthand the challenges small and medium-sized nut processing businesses face: labor-intensive manual sorting, inconsistent quality control, and rising production costs. Today, I’m excited to introduce a breakthrough ...

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

In the highly competitive realm of nuts processing, having the right tools can make all the difference. When it comes to hazelnut processing, the Hazelnut color sorter , plays a pivotal role. And WESORT's offerings in this domain are nothing short...

With the continuous development of the hazelnut industry, higher requirements are put forward for the sorting process in the hazelnut processing. The integrated solution of Hazelnut color and shell sorting launched by us aims to provide enterprises...

In the dynamic world of the food processing industry, the process of sorting beans plays a pivotal role. But what does it mean to sort beans exactly? Sorting beans is the meticulous process of separating them based on various characteristics such a...

Colour Sorter for Grain - Elevating Agricultural Product Standards WESORT Grain Sorter removes defective grains from a stock of uneven quality products! Suitable for all grains (wheat, barley, rye, etc.), even peas and beans. Moldy, broken, gre...

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in ...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...