Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 199 2458 0075

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in rice, cereals, nuts, industrial and other industries.

It is especially suitable for rice, tea, sesame, beans, melon seeds, peanuts, cottonseed, wolfberry, pepper, seeds, dried shrimps, etc. The effect of sorting impurities and special materials such as raisins, traditional Chinese medicine, glass, plastics, cinders, ores, and special materials is very remarkable and has reached the international leading level.

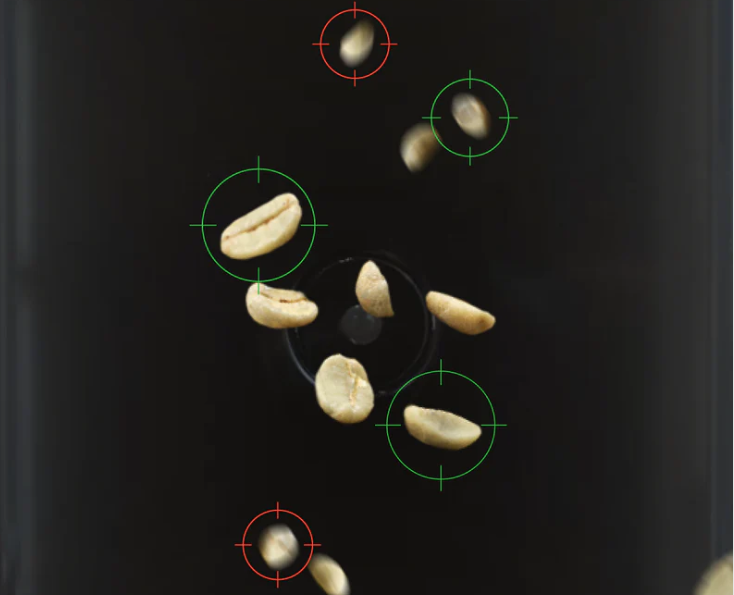

First, connect the power supply, turn on the tablet, touch the touch screen to start color selection; then pour the material to be selected for color into the vibrating feeding hopper, and use the high-frequency vibration of the feeder to shake the material and drop it into the material distribution slot; when the material falls into the dividing When selecting a box, two multi-megapixel cameras at the front and rear will comprehensively take high-frequency photos of each material, so as not to miss any blind spots.

The pictures will be compared with qualified materials through spectral analysis, and it will be found that materials that are inconsistent with qualified products, have different colors, and the air valve will Unqualified materials are blown into the overflow outlet, and qualified materials fall into the qualified material outlet along the set route.

The main components of the color sorter are feed hopper, vibrating feeder, chute, light source, background plate, CCD lens, discharge hopper, nozzle, air compressor, air storage tank, and filter.

1.Feeding system

It consists of a hopper, a vibrating feeder and a chute. The raw materials enter the vibrating feeder from the feeding hopper, and are automatically arranged into a series of continuous streamlines through the vibration and guiding mechanism, and after being accelerated by the chute, they drop to the detection area at a uniform speed. To ensure that the materials are clearly present in the sorting cabinet. In addition to the function of providing raw materials, the feeding system also controls the production capacity of the color sorter. Sorting per unit time can be realized.

2.Photoelectric system

The photoelectric system is the core part of the color sorter, which is mainly composed of LED light source, background board, CCD lens and related auxiliary equipment. The light source provides stable and uniform illumination for the tested material and the background board. The CCD lens converts the reflected light of the tested material into electrical signals in the detection area. The background board provides a reference signal for the electronic control system.

3.Sorting system

The sorting system consists of sorting cabinets, nozzles, air supply and other accessories. Experiments have proved that the nozzle spacing and the number of nozzles are one of the key factors that affect the accuracy of the color sorter.

4.Cleaning system

The cleaning system is composed of cylinders, glass cleaning brushes and other components. Because some items contain dust and other impurities, they may stick to the glass during the color classification process. Once dust and impurities adhere to the car window glass, the photoelectric system may cause interlocking problems such as false detection, thereby affecting the color selection accuracy and carry-over rate.

5.Operating system

The large-screen wide-angle touch screen is used to preset a variety of color selection modes for customers. And establish a friendly man-machine interface, which can be adjusted conveniently and quickly according to the specific conditions of the material.

Compared with manual sorting, it saves labor, time, high efficiency and low processing costs. Improve the quality and social and economic benefits of the selected products.

Although manufacturers produce different types of color sorters, most belong to the following three main types:

1.Chute color sorters

The product chutes of chute sorters are equipped with rows of optical sensors that can operate simultaneously to ensure comprehensive and accurate detection. These machines can quickly sort large quantities of materials and are ideal for high-capacity production lines.

2.Belt color sorters

This type of sorter uses a conveyor belt to transport materials through a single optical sensor. Because the objects do not move much, they are not easily damaged, so many companies use this type of sorter to sort fragile items.

3.Optical color sorters

Optical color sorting uses lasers or cameras to automatically sort bulk products. This non-destructive machine can identify the structure, shape, defect size and chemical composition of the product with a detection rate of 100%.

WESORT color sorters have higher quality color sorting products, and the products have a great advantage in peer competition, which helps to enhance the brand and reputation. Help customers solve quality problems and help customers grow bigger and stronger.

The color sorter is a device that uses photoelectric technology to automatically sort out the heterochromatic particles in granular materials based on the color differences of the materials. It is widely used in many fields and is widely used in rice, cereals, nuts, industrial and other industries.

It is especially suitable for rice, tea, sesame, beans, melon seeds, peanuts, cottonseed, wolfberry, pepper, seeds, dried shrimps, etc. The effect of sorting impurities and special materials such as raisins, traditional Chinese medicine, glass, plastics, cinders, ores, and special materials is very remarkable and has reached the international leading level.

First, connect the power supply, turn on the tablet, touch the touch screen to start color selection; then pour the material to be selected for color into the vibrating feeding hopper, and use the high-frequency vibration of the feeder to shake the material and drop it into the material distribution slot; when the material falls into the dividing When selecting a box, two multi-megapixel cameras at the front and rear will comprehensively take high-frequency photos of each material, so as not to miss any blind spots.

The pictures will be compared with qualified materials through spectral analysis, and it will be found that materials that are inconsistent with qualified products, have different colors, and the air valve will Unqualified materials are blown into the overflow outlet, and qualified materials fall into the qualified material outlet along the set route.

The main components of the color sorter are feed hopper, vibrating feeder, chute, light source, background plate, CCD lens, discharge hopper, nozzle, air compressor, air storage tank, and filter.

1.Feeding system

It consists of a hopper, a vibrating feeder and a chute. The raw materials enter the vibrating feeder from the feeding hopper, and are automatically arranged into a series of continuous streamlines through the vibration and guiding mechanism, and after being accelerated by the chute, they drop to the detection area at a uniform speed. To ensure that the materials are clearly present in the sorting cabinet. In addition to the function of providing raw materials, the feeding system also controls the production capacity of the color sorter. Sorting per unit time can be realized.

2.Photoelectric system

The photoelectric system is the core part of the color sorter, which is mainly composed of LED light source, background board, CCD lens and related auxiliary equipment. The light source provides stable and uniform illumination for the tested material and the background board. The CCD lens converts the reflected light of the tested material into electrical signals in the detection area. The background board provides a reference signal for the electronic control system.

3.Sorting system

The sorting system consists of sorting cabinets, nozzles, air supply and other accessories. Experiments have proved that the nozzle spacing and the number of nozzles are one of the key factors that affect the accuracy of the color sorter.

4.Cleaning system

The cleaning system is composed of cylinders, glass cleaning brushes and other components. Because some items contain dust and other impurities, they may stick to the glass during the color classification process. Once dust and impurities adhere to the car window glass, the photoelectric system may cause interlocking problems such as false detection, thereby affecting the color selection accuracy and carry-over rate.

5.Operating system

The large-screen wide-angle touch screen is used to preset a variety of color selection modes for customers. And establish a friendly man-machine interface, which can be adjusted conveniently and quickly according to the specific conditions of the material.

Compared with manual sorting, it saves labor, time, high efficiency and low processing costs. Improve the quality and social and economic benefits of the selected products.

Although manufacturers produce different types of color sorters, most belong to the following three main types:

1.Chute color sorters

The product chutes of chute sorters are equipped with rows of optical sensors that can operate simultaneously to ensure comprehensive and accurate detection. These machines can quickly sort large quantities of materials and are ideal for high-capacity production lines.

2.Belt color sorters

This type of sorter uses a conveyor belt to transport materials through a single optical sensor. Because the objects do not move much, they are not easily damaged, so many companies use this type of sorter to sort fragile items.

3.Optical color sorters

Optical color sorting uses lasers or cameras to automatically sort bulk products. This non-destructive machine can identify the structure, shape, defect size and chemical composition of the product with a detection rate of 100%.

WESORT color sorters have higher quality color sorting products, and the products have a great advantage in peer competition, which helps to enhance the brand and reputation. Help customers solve quality problems and help customers grow bigger and stronger.

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

In the highly competitive realm of nuts processing, having the right tools can make all the difference. When it comes to hazelnut processing, the Hazelnut color sorter , plays a pivotal role. And WESORT's offerings in this domain are nothing short...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

In the competitive world of agriculture, seed quality is crucial to achieving optimal crop yields and healthy, consistent growth. Whether you're cultivating field crops, herbage, or vegetables, ensuring that your seeds are free from defects and con...

Achieving the best quality in coffee roasting requires precision, and bean sorting plays a pivotal role in ensuring every cup meets the highest standards. Whether you're a small artisan roaster or part of a large-scale coffee production facility, i...

Plastic Sorting Made Easy with WESORT In today’s plastic recycling industry, achieving high-purity materials is crucial for profitability and sustainability. WESORT offers advanced optical sorting solutions designed to enhance both yield and quali...

Coffee, as one of the most popular drinks in the world, has a rigorous process behind it from coffee beans to every cup of fragrant coffee in the hands of consumers, and the color sorting link is the key to ensuring the quality of coffee. Today, I ...

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts: I. Picking and preliminary ...

In today’s competitive coffee market, quality is everything. Every bean that makes it into your blend must be perfect, ensuring the best flavor, aroma, and consistency in every cup. Our cutting-edge AI-powered single-channel coffee bean optical so...

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor pr...

Some time ago, I’ve witnessed firsthand the challenges small and medium-sized nut processing businesses face: labor-intensive manual sorting, inconsistent quality control, and rising production costs. Today, I’m excited to introduce a breakthrough ...

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

In the highly competitive realm of nuts processing, having the right tools can make all the difference. When it comes to hazelnut processing, the Hazelnut color sorter , plays a pivotal role. And WESORT's offerings in this domain are nothing short...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...