Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 199 2458 0075

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor profile in every cup. One breakthrough that has dramatically transformed the industry is optical sorting technology. This long-form article explores how modern optical sorting machines are revolutionizing coffee bean processing, drawing insights from industry leaders and cutting-edge manufacturers.

The Evolution of Coffee Bean Sorting

Traditionally, coffee bean sorting was a labor-intensive process that relied on manual inspection. Workers would sort beans by hand, identifying defects, discolorations, and impurities. However, this method was not only time-consuming but also prone to human error and inconsistency. As global demand for high-quality coffee grew, the need for an automated, precise, and efficient sorting solution became undeniable.

Enter optical sorting—a technology that leverages advanced imaging, sensors, and artificial intelligence to identify and remove undesirable beans. According to Counter Culture Coffee, optical sorting represents one of the most exciting advancements in coffee processing, offering a new level of accuracy and efficiency that was previously unattainable in manual sorting processes.

How Optical Sorting Technology Works

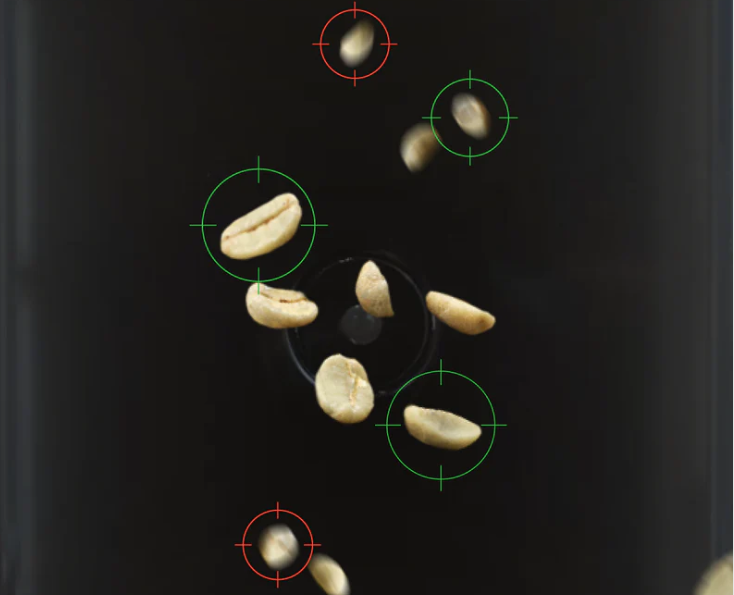

At the heart of optical sorting is a sophisticated integration of high-speed cameras, sensors, and intelligent algorithms. Here’s a closer look at the process:

1. High-Resolution Imaging:

Optical sorters use high-resolution cameras to capture detailed images of coffee beans as they pass through the machine at high speeds. This imaging technology is capable of detecting minute differences in color, shape, and size.

2. Sensor Analysis and AI Integration:

Advanced sensors analyze these images in real time. Machine learning algorithms compare the captured images against preset standards for quality. The system is finely tuned to distinguish between healthy beans and those that are discolored, malformed, or otherwise defective. This technology, as highlighted , allows for precise removal of even the smallest impurities, ensuring that only the best beans continue along the production line.

3. Automated Sorting Mechanism:

Once defective beans are identified, the system activates an air jet or mechanical diverter to remove them from the batch. This process is executed in milliseconds, which means the machine can handle large volumes of beans without sacrificing accuracy.

Benefits of Optical Sorting in Coffee Processing

The introduction of optical sorting technology has brought significant improvements across several key areas of coffee production:

- Enhanced Quality and Consistency:

Optical sorters ensure that only beans meeting strict quality standards are used, resulting in a more consistent flavor profile and improved overall quality of the final product. The removal of defective beans not only enhances taste but also prevents undesirable flavors from affecting the brew.

- Increased Efficiency and Reduced Labor Costs:

Automated sorting eliminates the need for labor-intensive manual inspection. This not only speeds up the production process but also reduces labor costs and minimizes human error, leading to a more efficient workflow.

- Minimized Waste and Sustainability Benefits:

By precisely targeting only the defective beans, optical sorters significantly reduce waste. This precise separation contributes to a more sustainable production process by ensuring that a greater proportion of the harvested beans meet the high standards required for premium coffee.

- Improved Traceability and Data Collection:

Modern optical sorters come equipped with data-collection capabilities that allow producers to track the quality of their beans throughout the sorting process. This data can be used to refine production methods, troubleshoot issues, and maintain high-quality standards over time.

Innovations Driving Modern Coffee Sorters

Leading companies in the field have continuously pushed the boundaries of optical sorting technology. For instance, WESORT has developed an advanced colour sorter that utilizes artificial intelligence and state-of-the-art imaging to detect even the subtlest color differences. Their system is designed to adapt and learn from each sorting cycle, improving accuracy and efficiency with every use.

companies like WESORT have integrated these innovations into large-scale production lines, making it possible to process vast quantities of coffee beans without compromising on quality. Their optical sorting solutions are engineered for robustness, speed, and precision—qualities that are indispensable in today’s competitive coffee market.

Industry Impact and Case Studies

The widespread adoption of optical sorting technology is having a transformative effect on the coffee industry. Producers are now able to deliver consistently high-quality products that meet the growing demands of discerning consumers. For example:

- Quality Control:

Coffee roasters and producers report a significant reduction in the number of defective beans reaching the roasting stage. This leads to better tasting coffee and fewer quality-related complaints from customers.

- Operational Efficiency:

The automation provided by optical sorters has streamlined processing operations, enabling companies to scale production without a proportional increase in labor costs. This efficiency has been crucial for meeting rising global demand.

- Market Competitiveness:

By ensuring a consistent and high-quality product, producers using optical sorting technology can position themselves as premium brands in the marketplace. The investment in high-tech sorting solutions often translates into better market prices and stronger brand loyalty.

Future Perspectives

The future of coffee bean processing looks bright, with optical sorting technology set to become even more advanced. Continued advancements in artificial intelligence and sensor technology are expected to further refine sorting accuracy and speed. Integration with Internet of Things (IoT) platforms will enable real-time monitoring and predictive maintenance, ensuring that optical sorting systems are always operating at peak performance.

Moreover, as the coffee industry continues to emphasize sustainability, the precision of optical sorters in reducing waste will become an increasingly important selling point. Future machines may also incorporate more sophisticated data analytics, providing coffee producers with deeper insights into their production processes and opportunities for continuous improvement.

Optical sorting technology represents a significant leap forward in coffee bean processing. By leveraging high-resolution imaging, advanced sensors, and intelligent algorithms, modern optical sorters ensure that only the finest beans make it to your cup. This technology not only enhances product quality and consistency but also drives operational efficiency and sustainability across the coffee supply chain.

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor profile in every cup. One breakthrough that has dramatically transformed the industry is optical sorting technology. This long-form article explores how modern optical sorting machines are revolutionizing coffee bean processing, drawing insights from industry leaders and cutting-edge manufacturers.

The Evolution of Coffee Bean Sorting

Traditionally, coffee bean sorting was a labor-intensive process that relied on manual inspection. Workers would sort beans by hand, identifying defects, discolorations, and impurities. However, this method was not only time-consuming but also prone to human error and inconsistency. As global demand for high-quality coffee grew, the need for an automated, precise, and efficient sorting solution became undeniable.

Enter optical sorting—a technology that leverages advanced imaging, sensors, and artificial intelligence to identify and remove undesirable beans. According to Counter Culture Coffee, optical sorting represents one of the most exciting advancements in coffee processing, offering a new level of accuracy and efficiency that was previously unattainable in manual sorting processes.

How Optical Sorting Technology Works

At the heart of optical sorting is a sophisticated integration of high-speed cameras, sensors, and intelligent algorithms. Here’s a closer look at the process:

1. High-Resolution Imaging:

Optical sorters use high-resolution cameras to capture detailed images of coffee beans as they pass through the machine at high speeds. This imaging technology is capable of detecting minute differences in color, shape, and size.

2. Sensor Analysis and AI Integration:

Advanced sensors analyze these images in real time. Machine learning algorithms compare the captured images against preset standards for quality. The system is finely tuned to distinguish between healthy beans and those that are discolored, malformed, or otherwise defective. This technology, as highlighted , allows for precise removal of even the smallest impurities, ensuring that only the best beans continue along the production line.

3. Automated Sorting Mechanism:

Once defective beans are identified, the system activates an air jet or mechanical diverter to remove them from the batch. This process is executed in milliseconds, which means the machine can handle large volumes of beans without sacrificing accuracy.

Benefits of Optical Sorting in Coffee Processing

The introduction of optical sorting technology has brought significant improvements across several key areas of coffee production:

- Enhanced Quality and Consistency:

Optical sorters ensure that only beans meeting strict quality standards are used, resulting in a more consistent flavor profile and improved overall quality of the final product. The removal of defective beans not only enhances taste but also prevents undesirable flavors from affecting the brew.

- Increased Efficiency and Reduced Labor Costs:

Automated sorting eliminates the need for labor-intensive manual inspection. This not only speeds up the production process but also reduces labor costs and minimizes human error, leading to a more efficient workflow.

- Minimized Waste and Sustainability Benefits:

By precisely targeting only the defective beans, optical sorters significantly reduce waste. This precise separation contributes to a more sustainable production process by ensuring that a greater proportion of the harvested beans meet the high standards required for premium coffee.

- Improved Traceability and Data Collection:

Modern optical sorters come equipped with data-collection capabilities that allow producers to track the quality of their beans throughout the sorting process. This data can be used to refine production methods, troubleshoot issues, and maintain high-quality standards over time.

Innovations Driving Modern Coffee Sorters

Leading companies in the field have continuously pushed the boundaries of optical sorting technology. For instance, WESORT has developed an advanced colour sorter that utilizes artificial intelligence and state-of-the-art imaging to detect even the subtlest color differences. Their system is designed to adapt and learn from each sorting cycle, improving accuracy and efficiency with every use.

companies like WESORT have integrated these innovations into large-scale production lines, making it possible to process vast quantities of coffee beans without compromising on quality. Their optical sorting solutions are engineered for robustness, speed, and precision—qualities that are indispensable in today’s competitive coffee market.

Industry Impact and Case Studies

The widespread adoption of optical sorting technology is having a transformative effect on the coffee industry. Producers are now able to deliver consistently high-quality products that meet the growing demands of discerning consumers. For example:

- Quality Control:

Coffee roasters and producers report a significant reduction in the number of defective beans reaching the roasting stage. This leads to better tasting coffee and fewer quality-related complaints from customers.

- Operational Efficiency:

The automation provided by optical sorters has streamlined processing operations, enabling companies to scale production without a proportional increase in labor costs. This efficiency has been crucial for meeting rising global demand.

- Market Competitiveness:

By ensuring a consistent and high-quality product, producers using optical sorting technology can position themselves as premium brands in the marketplace. The investment in high-tech sorting solutions often translates into better market prices and stronger brand loyalty.

Future Perspectives

The future of coffee bean processing looks bright, with optical sorting technology set to become even more advanced. Continued advancements in artificial intelligence and sensor technology are expected to further refine sorting accuracy and speed. Integration with Internet of Things (IoT) platforms will enable real-time monitoring and predictive maintenance, ensuring that optical sorting systems are always operating at peak performance.

Moreover, as the coffee industry continues to emphasize sustainability, the precision of optical sorters in reducing waste will become an increasingly important selling point. Future machines may also incorporate more sophisticated data analytics, providing coffee producers with deeper insights into their production processes and opportunities for continuous improvement.

Optical sorting technology represents a significant leap forward in coffee bean processing. By leveraging high-resolution imaging, advanced sensors, and intelligent algorithms, modern optical sorters ensure that only the finest beans make it to your cup. This technology not only enhances product quality and consistency but also drives operational efficiency and sustainability across the coffee supply chain.

Some time ago, I’ve witnessed firsthand the challenges small and medium-sized nut processing businesses face: labor-intensive manual sorting, inconsistent quality control, and rising production costs. Today, I’m excited to introduce a breakthrough ...

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

The coffee industry has seen significant advancements over the years, and one of the most impactful innovations is the introduction of the coffee sorting machine. Traditionally, coffee bean sorting has been a labor-intensive process with high poten...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

In the competitive world of agriculture, seed quality is crucial to achieving optimal crop yields and healthy, consistent growth. Whether you're cultivating field crops, herbage, or vegetables, ensuring that your seeds are free from defects and con...

Achieving the best quality in coffee roasting requires precision, and bean sorting plays a pivotal role in ensuring every cup meets the highest standards. Whether you're a small artisan roaster or part of a large-scale coffee production facility, i...

Plastic Sorting Made Easy with WESORT In today’s plastic recycling industry, achieving high-purity materials is crucial for profitability and sustainability. WESORT offers advanced optical sorting solutions designed to enhance both yield and quali...

Coffee, as one of the most popular drinks in the world, has a rigorous process behind it from coffee beans to every cup of fragrant coffee in the hands of consumers, and the color sorting link is the key to ensuring the quality of coffee. Today, I ...

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts: I. Picking and preliminary ...

In today’s competitive coffee market, quality is everything. Every bean that makes it into your blend must be perfect, ensuring the best flavor, aroma, and consistency in every cup. Our cutting-edge AI-powered single-channel coffee bean optical so...

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor pr...

Some time ago, I’ve witnessed firsthand the challenges small and medium-sized nut processing businesses face: labor-intensive manual sorting, inconsistent quality control, and rising production costs. Today, I’m excited to introduce a breakthrough ...

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

The coffee industry has seen significant advancements over the years, and one of the most impactful innovations is the introduction of the coffee sorting machine. Traditionally, coffee bean sorting has been a labor-intensive process with high poten...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...