Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 199 2458 0075

In the realm of plastic manufacturing and recycling, the plastic color sorter has emerged as a game - changing technology. It is an essential tool that addresses the complex challenges associated with handling plastics in various industrial settings.

Understanding the Plastic Color Sorter Technology

The plastic color sorter is a marvel of modern engineering that combines optical sensors, image processing algorithms, and high - speed sorting mechanisms. At its core, it utilizes advanced spectrometers and high - resolution cameras. These spectrometers are capable of analyzing the spectral properties of plastics with remarkable precision. They can differentiate between various plastic types based on their unique spectral signatures, which are often associated with different colors. The cameras, on the other hand, capture detailed images of the plastic materials as they pass through the sorting system. The image processing algorithms then work to identify any color variations, flaws, or impurities within the plastic pieces.

Applications in Plastic Recycling

Sorting by Color in Mixed Plastic Waste

In plastic recycling, one of the most significant challenges is dealing with mixed plastic waste. Different types of plastics often come in a variety of colors. A plastic color sorter can accurately separate plastics based on their color, which is crucial for subsequent recycling processes. For example, in a recycling facility handling post - consumer plastic bottles, the sorter can distinguish between clear PET bottles and colored PET bottles. This allows recyclers to process each type separately, maximizing the value of the recycled material. Clear PET can be used in high - quality applications such as food - grade packaging, while colored PET may be used in non - food - related products or remanufactured into colored plastic items.

Removal of Contaminated and Discolored Plastics

Plastic waste often contains contaminated or discolored pieces. These may be due to exposure to environmental factors, chemical reactions during use, or improper storage. The plastic color sorter can identify and remove these unwanted plastics. In the case of HDPE plastics used in milk jugs, for instance, any jugs with discoloration caused by sunlight exposure or chemical degradation can be sorted out. This ensures that the recycled HDPE maintains its quality and can be used to produce new, high - performance products such as durable plastic containers or pipes.

Identification of Different Plastic Resins

Beyond color sorting, the plastic color sorter can also identify different plastic resins. Plastics like PP, PE, PVC, and ABS have distinct optical properties that the sorter's sensors can detect. This ability is invaluable in recycling plants as it enables the separation of different plastic types. For example, separating PVC from other plastics is essential because PVC has different melting and processing requirements. By accurately identifying and sorting PVC, recyclers can prevent contamination of other plastic streams during the recycling process, improving the overall quality of the recycled plastics.

Advantages in Plastic Processing

Quality Control in Plastic Product Manufacturing

In plastic product manufacturing, maintaining color consistency is vital for product aesthetics and quality. The plastic color sorter can be used to ensure that only plastics of the correct color are used in production. For example, in the production of plastic toys, where bright and consistent colors are desired, the sorter can screen out any plastic pellets with color variations. This results in toys with a more uniform and appealing appearance, enhancing customer satisfaction and brand reputation.

Increasing Production Efficiency

The plastic color sorter operates at high speeds, capable of processing large volumes of plastic materials in a short time. This significantly increases the efficiency of both recycling and manufacturing processes. In a plastic injection molding factory, the sorter can quickly supply the molding machines with the right color and type of plastic pellets, reducing production downtime and increasing overall output.

Cost Reduction and Resource Optimization

By accurately sorting plastics, the plastic color sorter reduces waste and maximizes the use of available plastic resources. In recycling, it increases the yield of high - quality recycled plastics, reducing the need for virgin plastic materials. In manufacturing, it minimizes the rejection of finished products due to color or quality issues related to plastic materials. This leads to cost savings in both raw material procurement and waste management.

Future Trends and Developments

The field of plastic color sorting is constantly evolving. With the increasing demand for sustainable plastic management, there is a growing focus on improving the accuracy and efficiency of these sorters. Research is underway to develop more advanced sensors that can detect even more subtle differences in plastic properties. Additionally, there is a trend towards integrating artificial intelligence and machine learning algorithms into plastic color sorters. These technologies will enable the sorters to adapt to new types of plastics and color variations more quickly, further enhancing their performance in the complex world of plastic recycling and processing.

In conclusion, the plastic color sorter is a vital component in the plastic industry, driving improvements in recycling, processing, and product quality. Its continuous development and application will play a crucial role in meeting the challenges of sustainable plastic management and the growing demands of the global market.

In the realm of plastic manufacturing and recycling, the plastic color sorter has emerged as a game - changing technology. It is an essential tool that addresses the complex challenges associated with handling plastics in various industrial settings.

Understanding the Plastic Color Sorter Technology

The plastic color sorter is a marvel of modern engineering that combines optical sensors, image processing algorithms, and high - speed sorting mechanisms. At its core, it utilizes advanced spectrometers and high - resolution cameras. These spectrometers are capable of analyzing the spectral properties of plastics with remarkable precision. They can differentiate between various plastic types based on their unique spectral signatures, which are often associated with different colors. The cameras, on the other hand, capture detailed images of the plastic materials as they pass through the sorting system. The image processing algorithms then work to identify any color variations, flaws, or impurities within the plastic pieces.

Applications in Plastic Recycling

Sorting by Color in Mixed Plastic Waste

In plastic recycling, one of the most significant challenges is dealing with mixed plastic waste. Different types of plastics often come in a variety of colors. A plastic color sorter can accurately separate plastics based on their color, which is crucial for subsequent recycling processes. For example, in a recycling facility handling post - consumer plastic bottles, the sorter can distinguish between clear PET bottles and colored PET bottles. This allows recyclers to process each type separately, maximizing the value of the recycled material. Clear PET can be used in high - quality applications such as food - grade packaging, while colored PET may be used in non - food - related products or remanufactured into colored plastic items.

Removal of Contaminated and Discolored Plastics

Plastic waste often contains contaminated or discolored pieces. These may be due to exposure to environmental factors, chemical reactions during use, or improper storage. The plastic color sorter can identify and remove these unwanted plastics. In the case of HDPE plastics used in milk jugs, for instance, any jugs with discoloration caused by sunlight exposure or chemical degradation can be sorted out. This ensures that the recycled HDPE maintains its quality and can be used to produce new, high - performance products such as durable plastic containers or pipes.

Identification of Different Plastic Resins

Beyond color sorting, the plastic color sorter can also identify different plastic resins. Plastics like PP, PE, PVC, and ABS have distinct optical properties that the sorter's sensors can detect. This ability is invaluable in recycling plants as it enables the separation of different plastic types. For example, separating PVC from other plastics is essential because PVC has different melting and processing requirements. By accurately identifying and sorting PVC, recyclers can prevent contamination of other plastic streams during the recycling process, improving the overall quality of the recycled plastics.

Advantages in Plastic Processing

Quality Control in Plastic Product Manufacturing

In plastic product manufacturing, maintaining color consistency is vital for product aesthetics and quality. The plastic color sorter can be used to ensure that only plastics of the correct color are used in production. For example, in the production of plastic toys, where bright and consistent colors are desired, the sorter can screen out any plastic pellets with color variations. This results in toys with a more uniform and appealing appearance, enhancing customer satisfaction and brand reputation.

Increasing Production Efficiency

The plastic color sorter operates at high speeds, capable of processing large volumes of plastic materials in a short time. This significantly increases the efficiency of both recycling and manufacturing processes. In a plastic injection molding factory, the sorter can quickly supply the molding machines with the right color and type of plastic pellets, reducing production downtime and increasing overall output.

Cost Reduction and Resource Optimization

By accurately sorting plastics, the plastic color sorter reduces waste and maximizes the use of available plastic resources. In recycling, it increases the yield of high - quality recycled plastics, reducing the need for virgin plastic materials. In manufacturing, it minimizes the rejection of finished products due to color or quality issues related to plastic materials. This leads to cost savings in both raw material procurement and waste management.

Future Trends and Developments

The field of plastic color sorting is constantly evolving. With the increasing demand for sustainable plastic management, there is a growing focus on improving the accuracy and efficiency of these sorters. Research is underway to develop more advanced sensors that can detect even more subtle differences in plastic properties. Additionally, there is a trend towards integrating artificial intelligence and machine learning algorithms into plastic color sorters. These technologies will enable the sorters to adapt to new types of plastics and color variations more quickly, further enhancing their performance in the complex world of plastic recycling and processing.

In conclusion, the plastic color sorter is a vital component in the plastic industry, driving improvements in recycling, processing, and product quality. Its continuous development and application will play a crucial role in meeting the challenges of sustainable plastic management and the growing demands of the global market.

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

In the highly competitive realm of nuts processing, having the right tools can make all the difference. When it comes to hazelnut processing, the Hazelnut color sorter , plays a pivotal role. And WESORT's offerings in this domain are nothing short...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

In the competitive world of agriculture, seed quality is crucial to achieving optimal crop yields and healthy, consistent growth. Whether you're cultivating field crops, herbage, or vegetables, ensuring that your seeds are free from defects and con...

Achieving the best quality in coffee roasting requires precision, and bean sorting plays a pivotal role in ensuring every cup meets the highest standards. Whether you're a small artisan roaster or part of a large-scale coffee production facility, i...

Plastic Sorting Made Easy with WESORT In today’s plastic recycling industry, achieving high-purity materials is crucial for profitability and sustainability. WESORT offers advanced optical sorting solutions designed to enhance both yield and quali...

Coffee, as one of the most popular drinks in the world, has a rigorous process behind it from coffee beans to every cup of fragrant coffee in the hands of consumers, and the color sorting link is the key to ensuring the quality of coffee. Today, I ...

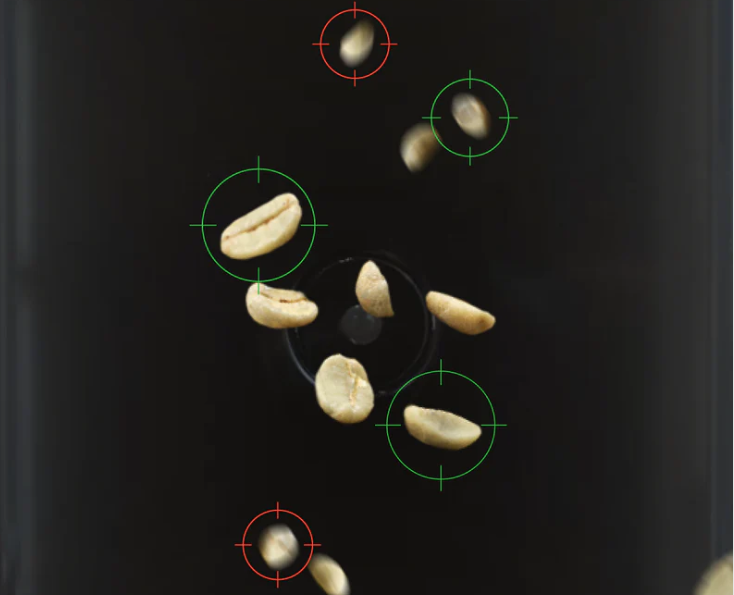

As a delicious and nutritious nut, the sorting process in the processing of hazelnuts plays a key role in the quality of the product. The following is a detailed introduction to the sorting and processing of hazelnuts: I. Picking and preliminary ...

In today’s competitive coffee market, quality is everything. Every bean that makes it into your blend must be perfect, ensuring the best flavor, aroma, and consistency in every cup. Our cutting-edge AI-powered single-channel coffee bean optical so...

Coffee is much more than just a beverage—it’s an experience shaped by the quality and consistency of the beans used. Over the years, coffee producers have continually sought ways to improve bean quality, reduce waste, and ensure a uniform flavor pr...

Some time ago, I’ve witnessed firsthand the challenges small and medium-sized nut processing businesses face: labor-intensive manual sorting, inconsistent quality control, and rising production costs. Today, I’m excited to introduce a breakthrough ...

In the Chinese color sorter market, if you only choose one brand, WESORT is usually the choice with the strongest comprehensive strength. Here are the specific reasons: 1. Industry status and technical advantages Leading market share: WESORT is t...

In the world of coffee, the journey from cherry to cup is a delicate and intricate process. Every step matters, and the quality of coffee cherries plays a crucial role in determining the final flavor profile of your beloved brew. This is where the ...

In the vibrant and competitive world of coffee production, the quality of coffee beans is the cornerstone of success. This is where the right Coffee bean color sorter - whether you call it a coffee bean colour sorter, coffee bean color sorting mach...

In the highly competitive realm of nuts processing, having the right tools can make all the difference. When it comes to hazelnut processing, the Hazelnut color sorter , plays a pivotal role. And WESORT's offerings in this domain are nothing short...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...