Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 181 2370 6862

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify the different-colored particles, impurities and defective peanuts in the peanuts. Whether it is peanuts that have changed color due to pests and diseases, or foreign objects such as small stones mixed in, the color sorter can identify and remove them one by one.

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify the different-colored particles, impurities and defective peanuts in the peanuts. Whether it is peanuts that have changed color due to pests and diseases, or foreign objects such as small stones mixed in, the color sorter can identify and remove them one by one.

In the field of peanut processing, peanut color sorters are playing a vital role.

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify discolored particles, impurities and defective peanuts in peanuts. Whether it is peanuts that have changed color due to pests or diseases, or foreign objects such as small stones mixed in, the color sorter can identify and remove them one by one.

This color sorter has extremely high accuracy and stability. It can finely sort peanuts according to their color, shape, size and other characteristics to ensure that every peanut that passes the screening is of excellent quality. Whether used for oil extraction, food production or as seeds, peanuts processed by color sorters can meet different needs.

For peanut processing companies, peanut color sorters bring many significant advantages. First, it greatly improves production efficiency. The traditional manual screening method is not only slow, but also prone to fatigue and omissions. The color sorter can process a large amount of peanuts in a short time and quickly complete the sorting task, saving valuable time and labor costs for the company.

Secondly, the color sorter ensures the quality stability of peanut products. Through precise sorting, each batch of peanuts can maintain consistent high quality, enhancing the company's market competitiveness. At the same time, it also helps to enhance the company's brand image and make consumers more trustful and recognize the company's products.

In addition, the peanut color sorter is easy to operate and easy to maintain. Its intelligent operating system makes it easy for staff to get started without complex technical training. Moreover, the stability and reliability of the equipment are high, reducing maintenance costs and downtime, ensuring that the company's production can continue and stably.

In short, the peanut color sorter has become a powerful assistant in the peanut processing industry with its excellent performance and reliable quality. It brings efficient production methods and high-quality products to enterprises, and promotes the continuous development of the peanut industry.

In the field of peanut processing, peanut color sorters are playing a vital role.

The peanut color sorter uses advanced optical recognition technology and intelligent algorithms. It can quickly and accurately identify discolored particles, impurities and defective peanuts in peanuts. Whether it is peanuts that have changed color due to pests or diseases, or foreign objects such as small stones mixed in, the color sorter can identify and remove them one by one.

This color sorter has extremely high accuracy and stability. It can finely sort peanuts according to their color, shape, size and other characteristics to ensure that every peanut that passes the screening is of excellent quality. Whether used for oil extraction, food production or as seeds, peanuts processed by color sorters can meet different needs.

For peanut processing companies, peanut color sorters bring many significant advantages. First, it greatly improves production efficiency. The traditional manual screening method is not only slow, but also prone to fatigue and omissions. The color sorter can process a large amount of peanuts in a short time and quickly complete the sorting task, saving valuable time and labor costs for the company.

Secondly, the color sorter ensures the quality stability of peanut products. Through precise sorting, each batch of peanuts can maintain consistent high quality, enhancing the company's market competitiveness. At the same time, it also helps to enhance the company's brand image and make consumers more trustful and recognize the company's products.

In addition, the peanut color sorter is easy to operate and easy to maintain. Its intelligent operating system makes it easy for staff to get started without complex technical training. Moreover, the stability and reliability of the equipment are high, reducing maintenance costs and downtime, ensuring that the company's production can continue and stably.

In short, the peanut color sorter has become a powerful assistant in the peanut processing industry with its excellent performance and reliable quality. It brings efficient production methods and high-quality products to enterprises, and promotes the continuous development of the peanut industry.

MODEL 6SXZ-204 CAPACITY (KG/H) 1500-2400 ACCURAXY (%) ≥99 POWER (KW) 2.0-2.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1500 WEIGHT (KG) 440 DIMENSIONS(MM) 1616*1563*1652 Note : The above processing capacityis calculated based on the raw mat...

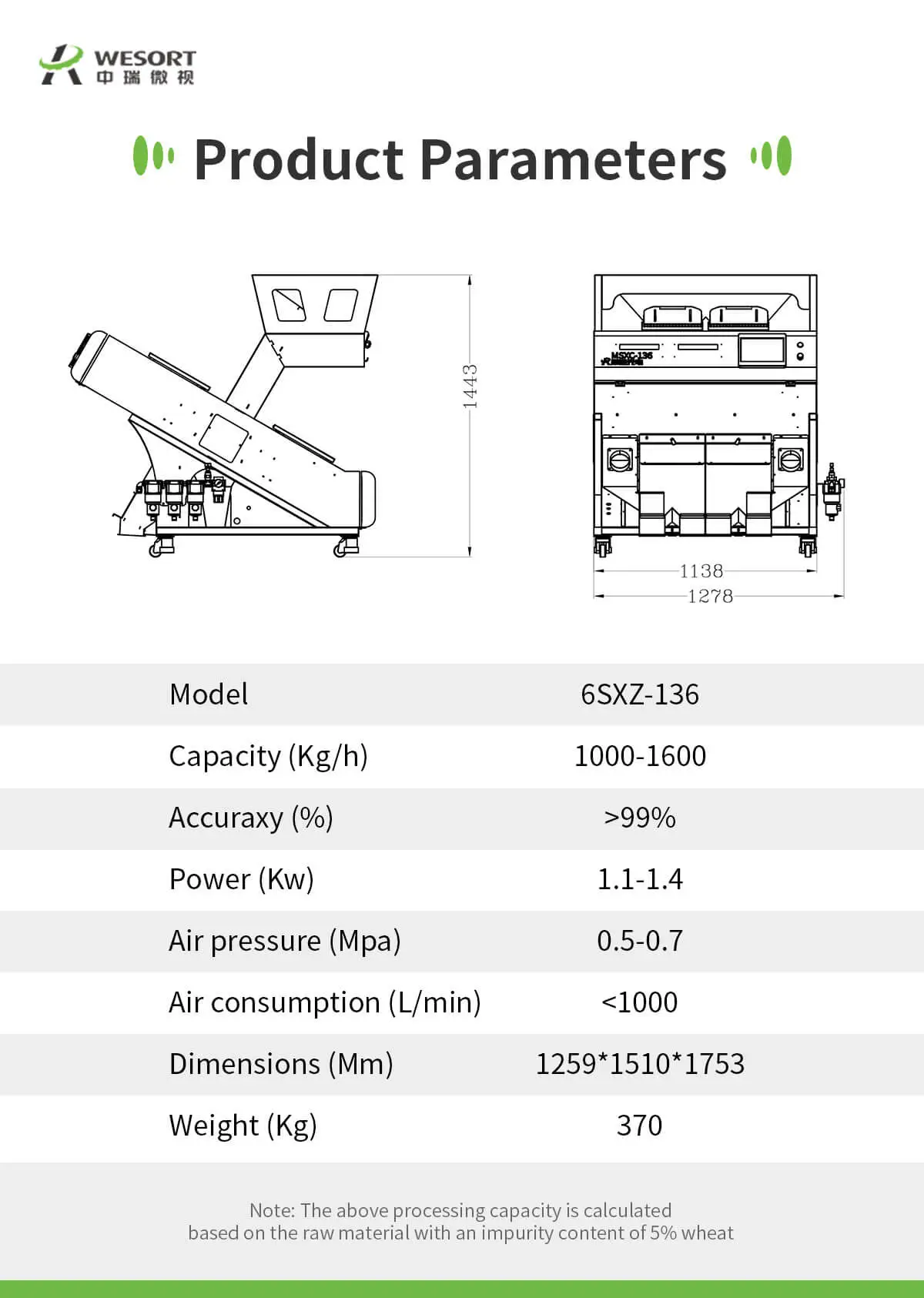

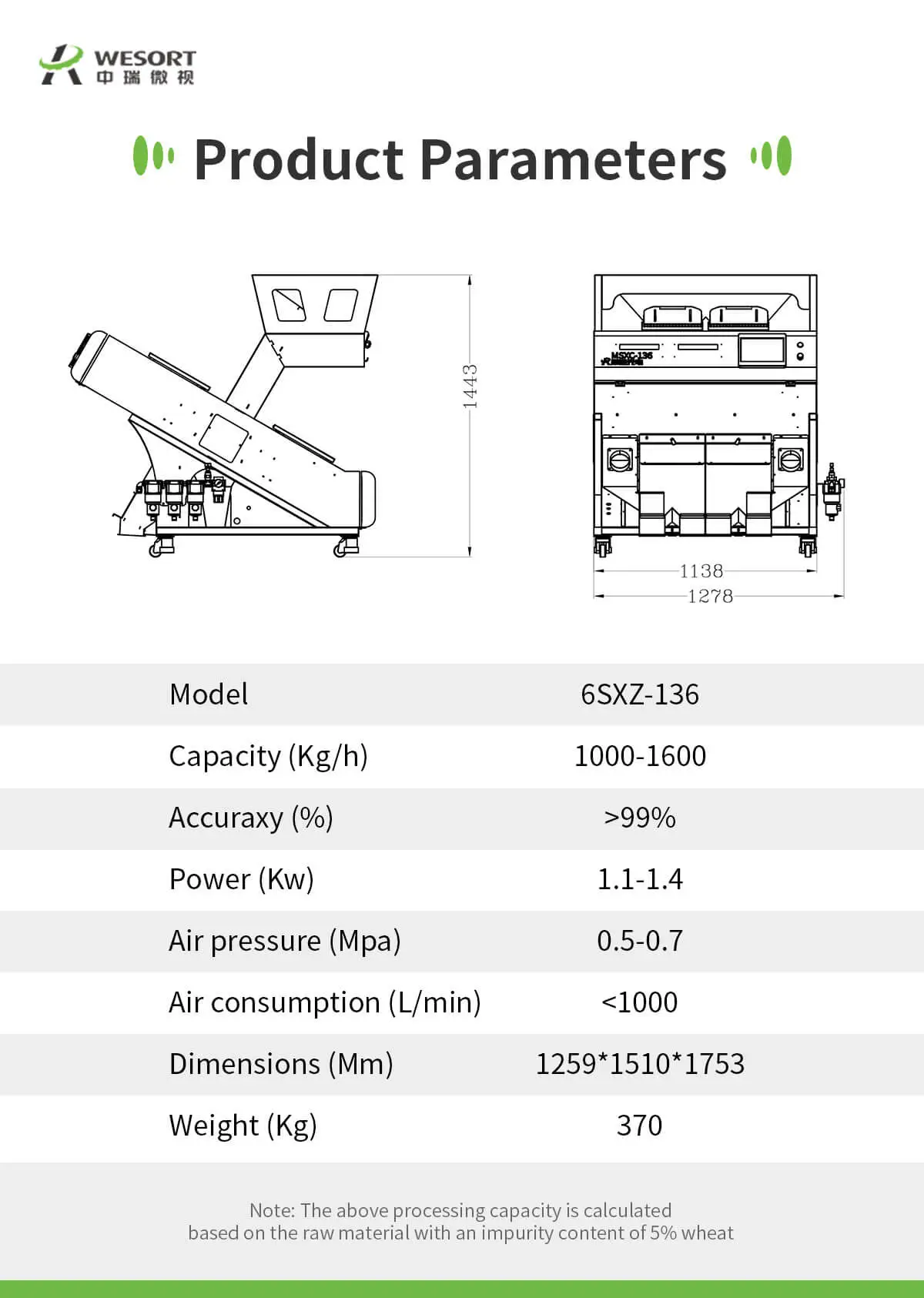

MODEL 6SXZ-136 CAPACITY (KG/H) 1000-1600 ACCURAXY (%) ≥99 POWER (KW) 1.4-1.8 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1000 WEIGHT (KG) 370 DIMENSIONS(MM) 1278*1566*1443 Note : The above processing capacityis calculated based on the raw mat...

Product model 6SXZ-136 Capacity (KG/H) 100-200 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 1.4-1.8 Air consumption (L/min) <1000 Weight(KG) 370 Size (mm) 1278*1566*1443

Product model 6SXZ-204 Capacity (KG/H) 150-300 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 2.0-2.4 Air consumption (L/min) <1500 Weight(KG) 440 Size (mm) 1616*1563*1652

Corn Color Sorter | High-Precision Optical Sorting Machine Product Description The WESORT Corn Color Sorter is a high-end optical sorting machine designed to deliver superior grain quality with advanced RGB CCD technology. Built for corn and multipur...

A multi-function wheat color sorter machine is designed to separate wheat grains based on color differences, helping to remove impurities and ensure higher quality in the final product. This color sorter is common equipment for flour grinding. It...

MODEL 6SXZ-90 CAPACITY (KG/H) 600-900 ACCURAXY (%) ≥99 POWER (KW) 1.0-1.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <750 WEIGHT (KG) 310 DIMENSIONS(MM) 990*1538*1996 Note : The above processing capacityis calculated based on the raw material...

MODEL 6SXZ-204 CAPACITY (KG/H) 1500-2400 ACCURAXY (%) ≥99 POWER (KW) 2.0-2.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1500 WEIGHT (KG) 440 DIMENSIONS(MM) 1616*1563*1652 Note : The above processing capacityis calculated based on the raw mat...

MODEL 6SXZ-136 CAPACITY (KG/H) 1000-1600 ACCURAXY (%) ≥99 POWER (KW) 1.4-1.8 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1000 WEIGHT (KG) 370 DIMENSIONS(MM) 1278*1566*1443 Note : The above processing capacityis calculated based on the raw mat...

Product model 6SXZ-136 Capacity (KG/H) 100-200 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 1.4-1.8 Air consumption (L/min) <1000 Weight(KG) 370 Size (mm) 1278*1566*1443

Product model 6SXZ-204 Capacity (KG/H) 150-300 Air source pressure(Mpa) 0.4-0.6 Power source(mpa) 220v 50hz Power (w) 2.0-2.4 Air consumption (L/min) <1500 Weight(KG) 440 Size (mm) 1616*1563*1652

Corn Color Sorter | High-Precision Optical Sorting Machine Product Description The WESORT Corn Color Sorter is a high-end optical sorting machine designed to deliver superior grain quality with advanced RGB CCD technology. Built for corn and multipur...

A multi-function wheat color sorter machine is designed to separate wheat grains based on color differences, helping to remove impurities and ensure higher quality in the final product. This color sorter is common equipment for flour grinding. It...

MODEL 6SXZ-90 CAPACITY (KG/H) 600-900 ACCURAXY (%) ≥99 POWER (KW) 1.0-1.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <750 WEIGHT (KG) 310 DIMENSIONS(MM) 990*1538*1996 Note : The above processing capacityis calculated based on the raw material...

MODEL 6SXZ-204 CAPACITY (KG/H) 1500-2400 ACCURAXY (%) ≥99 POWER (KW) 2.0-2.4 AIR PRESSURE (MPA) 0.4-0.6 GAS CONSUMPTION (L/MIN) <1500 WEIGHT (KG) 440 DIMENSIONS(MM) 1616*1563*1652 Note : The above processing capacityis calculated based on the raw mat...