Shenzhen Wesort Optoelectronics Co., Ltd.

Address:Building 29, Longwangmiao Industrial Zone, Fuyong street, Bao'an District, Shenzhen, Guangdong Province, China.

Phone:+86 199 2458 0075

At present, the color sorters on the market are mainly divided into two types: crawler color sorters and chute color sorters. Is it better to use a crawler type or a chute type for the color sorter? Which one is more efficient to use? Compared with the traditional chute color sorter, the crawler color sorter can highlight the advantages of the crawler in terms of color sorting accuracy, sorting damage rate, and processing output per hour. Therefore, the crawler color sorter is accepted by more and more customers, and the market share is gradually expanding.

The following editor introduces a sliding slot color sorter and a crawler color sorter, and the difference between the two.

1. What is a chute color sorter?

The chute color sorter uses gravity to make materials slide at a high speed along the chute. Some materials cannot slide at a constant speed or jump up and down during the sliding process, which makes the color sorting accuracy not high.

There are two very important links when the color sorter works, namely optical imaging and nozzles. The main function of optical imaging is to identify materials, and the nozzle is mainly to remove materials on the basis of identification. Inside the whole machine, there is a distance of about 10cm between the optical imaging point and the nozzle position, so the material needs a fixed delay and a stable running track from the position where the material is found to the position of the nozzle. The material jumps up and down on the chute machine, which causes the material to not run on the chute at a uniform speed. If the speed is inconsistent, the nozzle delay is also inconsistent, which will cause the nozzle to move in advance or delay, and ultimately lead to the decline of the color selection accuracy.

In addition, the up and down movement of the material actually affects the distance between the material and the optical imaging lens, resulting in blurred imaging, and also affects the distance between the material and the nozzle. Therefore, when the material is too far from the nozzle, the force of the nozzle on the material will be weakened, thereby reducing the color selection accuracy. 2. What is a crawler color sorter?

The crawler color sorter is to transport the materials to the sorting area by the conveyor of the crawler. During this process, the materials run at a constant speed and are relatively static, which can well maintain a fixed delay and a stable running track. This ensures the accuracy of color selection to the greatest extent.

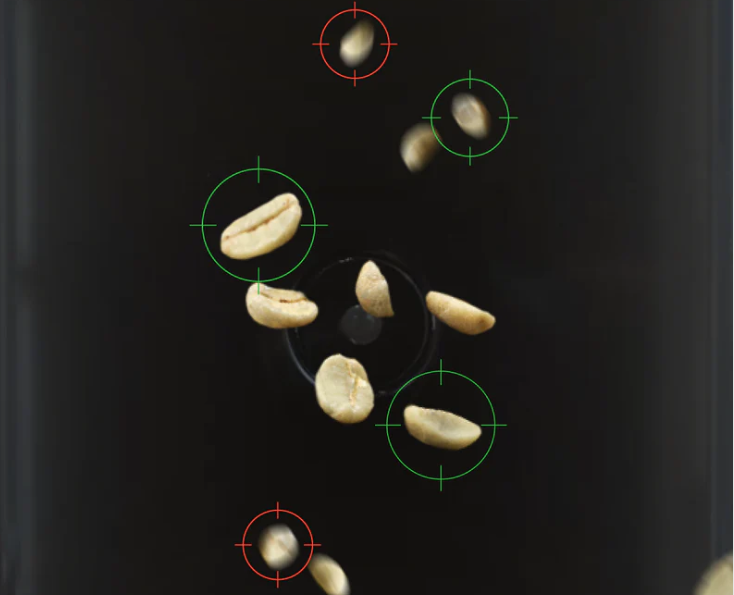

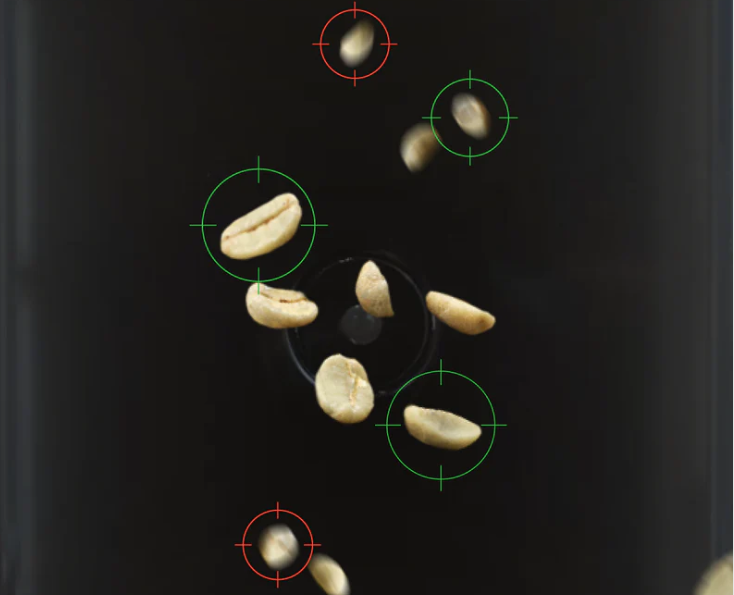

When the chute color sorter is running, the material is continuously accelerated from top to bottom. Even if the color sorting is completed, the material will still be accelerated for a period of time and distance, which will increase the damage to the material and result in a high rate of damage. However, the crawler color sorter does not have this defect. The material moves horizontally on the crawler and falls flat. The material does not have the problem of excessive acceleration, and the damage to the material is relatively minor and the damage is small. For materials that require high breakage rates such as peanuts, peanuts, peeled peanuts, garlic, tea, etc., Zhongrui Microvision's crawler color sorter has been verified on site by customers, and the effect is significant and the damage rate is very low.

3. Analysis of the scope of application of chute color sorter and crawler color sorter

In contrast, the chute color sorter, because the channel is designed according to the shape and size of the product, it is suitable for regular materials such as rice and wheat. For materials with large differences in shape and size, such as peanuts, plastics, ore, and tea, the color The selection effect is not ideal. With the continuous enrichment of the types of materials on the market and the continuous improvement of color sorting requirements, the chute color sorting machine has gradually not adapted to the development trend of the color sorting industry.

This is not the case for crawler color sorters, which are suitable for color sorting of various materials. In terms of color sorting output, the speed of the crawler color sorting machine is controllable and the output can be adjusted. The design is specifically based on the actual production of the customer. The chute color sorter has a fixed structure, a fixed speed, and a fixed output.

Compared with the chute machine, the crawler color sorter requires some moving parts and the structure is relatively complicated, so the cost is relatively high. However, in a comprehensive comparison, the economic benefits of the crawler color sorter are still far greater than the cost. 4. Choose plastic, which is better for color sorter with crawler type or chute type?

Therefore, compared with the chute color sorter, the crawler color sorter has the advantages of a wide range of optional materials, high color sorting accuracy, small damage, high output, and small carry-out ratio. All in all, the cost performance of the crawler color sorter is higher than that of the traditional chute color sorter. The ability to use mechanization to select high-quality products has promoted the sustainable development of the plastics industry and played a role in protecting the environment.

At present, the color sorters on the market are mainly divided into two types: crawler color sorters and chute color sorters. Is it better to use a crawler type or a chute type for the color sorter? Which one is more efficient to use? Compared with the traditional chute color sorter, the crawler color sorter can highlight the advantages of the crawler in terms of color sorting accuracy, sorting damage rate, and processing output per hour. Therefore, the crawler color sorter is accepted by more and more customers, and the market share is gradually expanding.

The following editor introduces a sliding slot color sorter and a crawler color sorter, and the difference between the two.

1. What is a chute color sorter?

The chute color sorter uses gravity to make materials slide at a high speed along the chute. Some materials cannot slide at a constant speed or jump up and down during the sliding process, which makes the color sorting accuracy not high.

There are two very important links when the color sorter works, namely optical imaging and nozzles. The main function of optical imaging is to identify materials, and the nozzle is mainly to remove materials on the basis of identification. Inside the whole machine, there is a distance of about 10cm between the optical imaging point and the nozzle position, so the material needs a fixed delay and a stable running track from the position where the material is found to the position of the nozzle. The material jumps up and down on the chute machine, which causes the material to not run on the chute at a uniform speed. If the speed is inconsistent, the nozzle delay is also inconsistent, which will cause the nozzle to move in advance or delay, and ultimately lead to the decline of the color selection accuracy.

In addition, the up and down movement of the material actually affects the distance between the material and the optical imaging lens, resulting in blurred imaging, and also affects the distance between the material and the nozzle. Therefore, when the material is too far from the nozzle, the force of the nozzle on the material will be weakened, thereby reducing the color selection accuracy. 2. What is a crawler color sorter?

The crawler color sorter is to transport the materials to the sorting area by the conveyor of the crawler. During this process, the materials run at a constant speed and are relatively static, which can well maintain a fixed delay and a stable running track. This ensures the accuracy of color selection to the greatest extent.

When the chute color sorter is running, the material is continuously accelerated from top to bottom. Even if the color sorting is completed, the material will still be accelerated for a period of time and distance, which will increase the damage to the material and result in a high rate of damage. However, the crawler color sorter does not have this defect. The material moves horizontally on the crawler and falls flat. The material does not have the problem of excessive acceleration, and the damage to the material is relatively minor and the damage is small. For materials that require high breakage rates such as peanuts, peanuts, peeled peanuts, garlic, tea, etc., Zhongrui Microvision's crawler color sorter has been verified on site by customers, and the effect is significant and the damage rate is very low.

3. Analysis of the scope of application of chute color sorter and crawler color sorter

In contrast, the chute color sorter, because the channel is designed according to the shape and size of the product, it is suitable for regular materials such as rice and wheat. For materials with large differences in shape and size, such as peanuts, plastics, ore, and tea, the color The selection effect is not ideal. With the continuous enrichment of the types of materials on the market and the continuous improvement of color sorting requirements, the chute color sorting machine has gradually not adapted to the development trend of the color sorting industry.

This is not the case for crawler color sorters, which are suitable for color sorting of various materials. In terms of color sorting output, the speed of the crawler color sorting machine is controllable and the output can be adjusted. The design is specifically based on the actual production of the customer. The chute color sorter has a fixed structure, a fixed speed, and a fixed output.

Compared with the chute machine, the crawler color sorter requires some moving parts and the structure is relatively complicated, so the cost is relatively high. However, in a comprehensive comparison, the economic benefits of the crawler color sorter are still far greater than the cost. 4. Choose plastic, which is better for color sorter with crawler type or chute type?

Therefore, compared with the chute color sorter, the crawler color sorter has the advantages of a wide range of optional materials, high color sorting accuracy, small damage, high output, and small carry-out ratio. All in all, the cost performance of the crawler color sorter is higher than that of the traditional chute color sorter. The ability to use mechanization to select high-quality products has promoted the sustainable development of the plastics industry and played a role in protecting the environment.

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

If your processing plant is not using a high-quality optical sorter, you may be missing out on an indispensable technology that can improve your production capacity and product quality. Modern Color sorters eliminate the need for time-consuming and...

Color sorters are used in food processing, resource recycling, ore mining and other industries, such as coffee beans, nuts and oil crops in the food industry, to separate crops that are discolored, toxic (such as moldy) or have not reached the requ...

In Indonesia, where coffee farming is both a tradition and a booming business, maintaining consistent bean quality is crucial for staying competitive. But how do you know if it's time to upgrade your coffee farm equipment in Indonesia? Here are f...

Still spending 3 hours sorting just 5 kg of beans? Manual sorting isn’t just time-consuming — it puts your entire roast at risk.One black bean can ruin an entire batch. Would you risk your quality on someone’s“feel”? Even the most experienced han...

If you're in the coffee industry, the right coffee sorting machine can significantly impact the quality of your final product. This comprehensive Coffee Sorting Machine Guide covers everything you need to know about choosing, using, and understandi...

Foreword: New challenges for coffee exporting countries Indonesia is one of the world's important coffee bean producers and exporters. However, as the international market continues to increase its requirements for coffee quality, manual selection ...

From May 15 to 17. 2025. the World of Coffee Jakarta will be held at the Jakarta Convention Center. As one of the most influential coffee industry events in Southeast Asia, the exhibition focuses on coffee planting, processing, equipment, technolog...

Indonesia’s coffee exports have long been recognized for their rich aroma and diverse bean varieties. But for one Sumatra-based coffee exporter, achieving international-grade consistency was a challenge — until they upgraded their processing line w...

Dear Coffee Professionals, You're Invited: Visit WESORT at the 2025 Jakarta Coffee Expo!Explore Innovation with Leading Indonesian Coffee Equipment Supplier – WESORT. Looking for innovative coffee sorting solutions from trusted Indonesian coffe...

Indonesia has long been one of the world’s top coffee-producing countries, renowned for its rich flavor profiles and unique regional varieties. But as global markets demand increasingly higher quality and consistency, exporters are under growing pr...

Event: World of Coffee – Jakarta, Indonesia Date: May 15-17. 2025 Opening Hours: 10:00 AM – 6:00 PM Venue: Jakarta Convention Center, Jl. Gatot Subroto No.1. RT.1/RW.3. Gelora, Kecamatan Tanah Abang, Kota Jakarta Pusat, Daerah Khusus Ibukota ...

The coffee industry has seen significant advancements over the years, and one of the most impactful innovations is the introduction of the coffee sorting machine. Traditionally, coffee bean sorting has been a labor-intensive process with high poten...

As a sales manager at Wesort, one of the most frequent questions I receive is: “How do customers feel about your coffee sorting machines?” The short answer? Our clients speak highly of both the performance and reliability of our machines — especial...

In today’s competitive global coffee market, quality is everything. As a sales manager working with international buyers, I’ve seen firsthand how a small defect in a coffee shipment can impact brand reputation, customer loyalty, and export value. T...

In the vibrant and coffee-rich landscapes of South America, quality control is no longer just a requirement — it’s a competitive edge. As a sales manager representing WESORT, I’ve had the privilege to witness firsthand how our coffee sorting machi...

In the ever-evolving European coffee market—where premium quality and sustainability go hand in hand—choosing the right coffee sorting machine is more than just a technical decision. It’s a strategic investment that directly impacts flavor consiste...

With the advancement of technology, people have begun to explore how to use artificial intelligence (AI) technology to improve the coffee bean screening process. In traditional screening methods, identifying defects in coffee beans usually requires...

In today’s competitive coffee market, quality is everything. Whether you’re exporting green beans or roasting for specialty coffee lovers, consistency and appearance are key to building a premium brand. That’s where the Wesort coffee color sorter...

When it comes to producing high-quality coffee, every step in the process plays an essential role. Among these, sorting coffee beans is one of the most critical stages. To ensure that only the best beans make it to your customers, investing in the ...

The flavor of coffee is closely related to its processing process, and the processing of each link directly affects the final quality of coffee beans. From the sorting of fresh coffee berries to the drying of raw coffee beans, and then to the roast...

If your processing plant is not using a high-quality optical sorter, you may be missing out on an indispensable technology that can improve your production capacity and product quality. Modern Color sorters eliminate the need for time-consuming and...

Color sorters are used in food processing, resource recycling, ore mining and other industries, such as coffee beans, nuts and oil crops in the food industry, to separate crops that are discolored, toxic (such as moldy) or have not reached the requ...

In Indonesia, where coffee farming is both a tradition and a booming business, maintaining consistent bean quality is crucial for staying competitive. But how do you know if it's time to upgrade your coffee farm equipment in Indonesia? Here are f...

Still spending 3 hours sorting just 5 kg of beans? Manual sorting isn’t just time-consuming — it puts your entire roast at risk.One black bean can ruin an entire batch. Would you risk your quality on someone’s“feel”? Even the most experienced han...